THERMOVISION

Case Study

Title: Revitalizing the Former Military District: Successful Thermal Modernization in Odessa

Introduction:

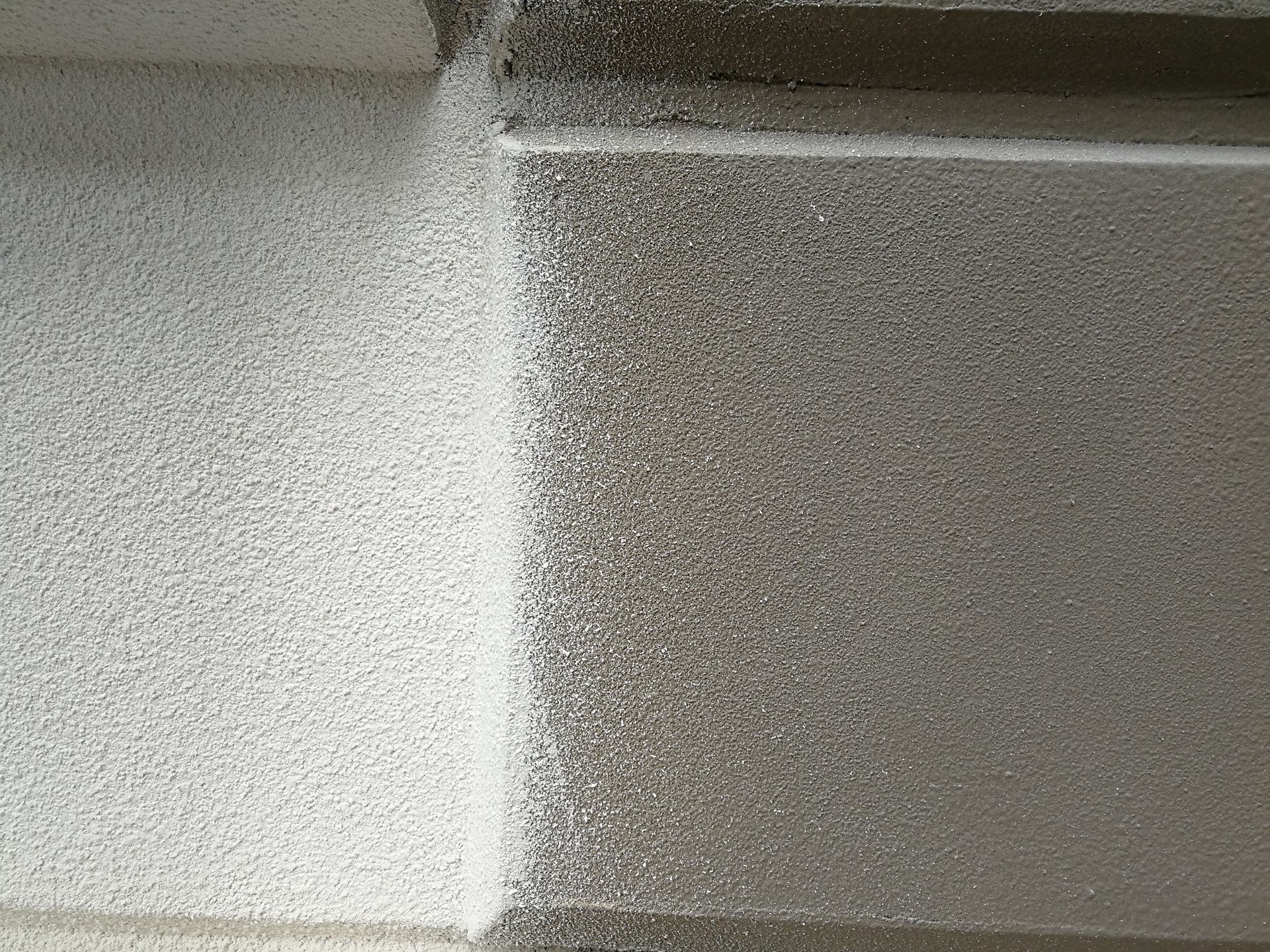

The former Military District in Odessa, Ukraine, has undergone a remarkable transformation through a comprehensive reconstruction project. The initiative included the thermal modernization of multiple buildings, focusing on enhancing energy efficiency and preserving the historical significance of the site. One notable aspect of this endeavor was the use of Spherolith coating, an innovative thermal insulation material, which effectively protected the exteriors against moisture and reduced heat loss. Let's delve deeper into the details of this successful project.

Spherolith Coating: A Game-Changer in Thermal Insulation

The decision to employ Spherolith coating proved to be a pivotal choice for the project. By utilizing this advanced thermal insulation material, the team achieved effective protection against moisture penetration while significantly improving the thermal resistance of external walls. The insulation layer, with a thickness of 3.5 mm, played a crucial role in minimizing heat loss. To maintain the aesthetic appeal of the buildings, the Spherolith coating was covered with a white façade plaster, providing a clean and visually pleasing appearance. The application process, involving mechanical spraying, ensured both high-quality results and efficient service delivery.

Impressive Scale and Conservation Considerations

The thermal modernization project covered an extensive area, encompassing a total of 7,500.00 m2 for the insulation of walls using the SFEROLIT preparation. However, it is important to note that while the project aimed to improve the energy efficiency of the buildings, the conservation of historical elements remained a top priority. The entire process was carried out under the strict control of the conservator of monuments, ensuring that the architectural integrity and cultural value of the structures were meticulously preserved.

Successful Completion and Future Prospects

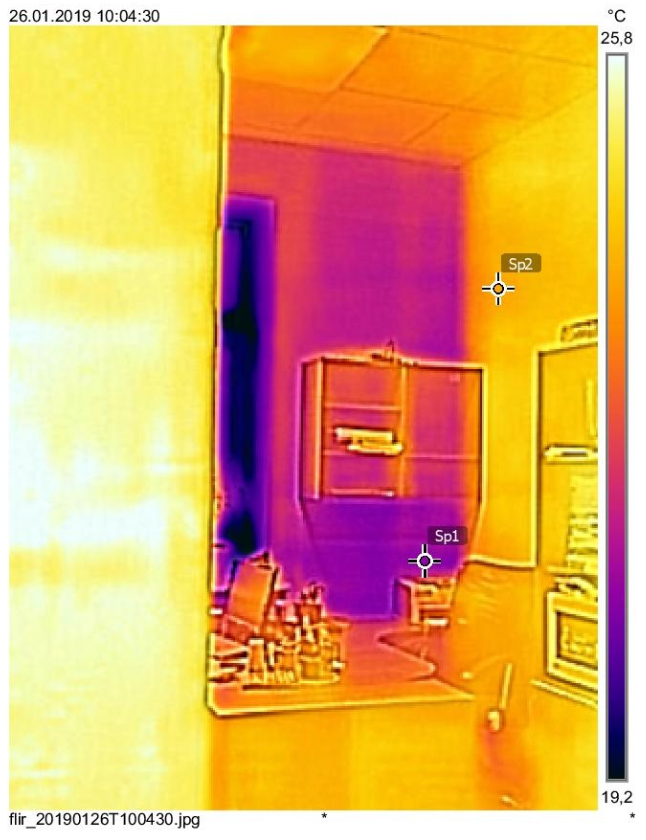

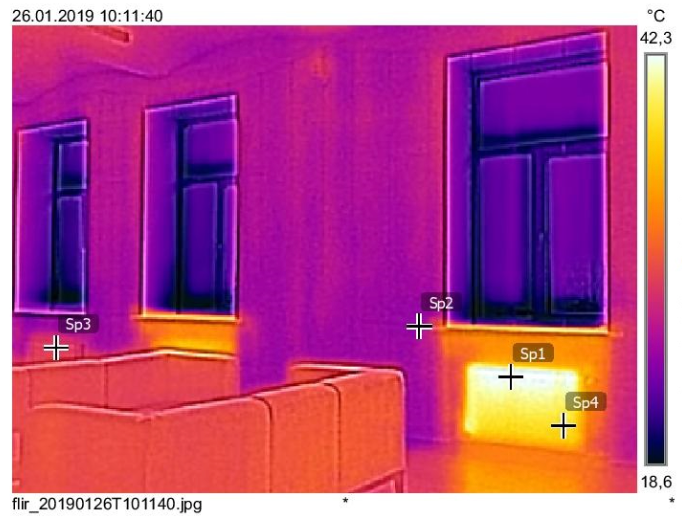

The thermal modernization project was successfully executed during the turn of 2017/2018 and has since proven its effectiveness. To assess the long-term impact of the improvements, a thermal imaging camera was employed for an inspection on January 26, 2019. The results confirmed the substantial benefits achieved through the integration of Spherolith coating, demonstrating improved thermal performance and energy efficiency.

Looking ahead, the revitalization of the former Military District in Odessa serves as a testament to the city's commitment to sustainable development and historical preservation. The successful implementation of thermal modernization techniques, particularly the utilization of Spherolith coating, highlights the potential for similar projects in the future. By embracing innovative solutions and maintaining a balance between energy efficiency and conservation, Odessa sets an example for other cities seeking to revitalize their historical districts while reducing environmental impact.

Conclusion:

The general reconstruction and thermal modernization of the former Military District in Odessa, Ukraine, showcases the remarkable potential of integrating advanced insulation materials like Spherolith coating. The successful completion of this project not only improves energy efficiency and reduces heat loss but also preserves the historical significance of the site. With a focus on sustainable development and conservation, Odessa paves the way for future transformations that blend modern innovation with architectural heritage.

Measurement

Bx1. Max

Min

Average

Bx2. Max

Min

Average

Sp1

Sp2

Sp3

Sp4

Sp5

Sp6

Sp7

Li1. Max

Min

Average

℃

-1.4

-2.5

-1.9

0.5

-3.3

-1.9

-2.4

-3.8

-2.5

-3.4

-1.7

-3.3

-2.1

-1.1

-2.2

-1.8

Parameter

Radiation factor

Reflection of temp.

Distance

Air temperature

External temp. optics

Exte. transmit. of optics

Relative humidity

-

0.95

20 ℃

1m

-4 ℃

20 ℃

1

50 %

Measurement

Sp1

Sp2

Sp3

Sp4

Sp5

Sp6

Sp7

Li1. Max

Min

Average

℃

-3.9

-0.8

-1.4

-0.1

-2.0

-2.2

-3.3

2.6

-1.0

0.6

Parameter

Radiation factor

Reflection of temp.

Distance

Air temperature

External temp. optics

Exte. transmit. of optics

Relative humidity

-

0.95

20 ℃

1m

-4 ℃

20 ℃

1

50 %

Measurement

Sp1

Sp2

℃

22.1

24.7

Parameter

Radiation factor

Reflection of temp.

Distance

Air temperature

External temp. optics

Exte. transmit. of optics

Relative humidity

-

0.95

20 ℃

1m

20 ℃

20 ℃

1

50 %

Measurement

Sp1

Sp2

Sp3

Sp4

℃

41.8

23.2

24.9

35.5

Parameter

Radiation factor

Reflection of temp.

Distance

Air temperature

External temp. optics

Exte. transmit. of optics

Relative humidity

-

0.95

20 ℃

1m

20 ℃

20 ℃

1

50 %

Measurement

Bx1 Max

Min

Average

℃

24.8

22.9

23.7

Parameter

Radiation factor

Reflection of temp.

Distance

Air temperature

External temp. optics

Exte. transmit. of optics

Relative humidity

-

0.95

20 ℃

1m

20 ℃

20 ℃

1

50 %