REALISATIONS

Realisations 1

Sferolit Coating as an Efficient Thermal Insulation Material for an Office Building

Introduction:

This case study explores the successful implementation of Sferolit coating as a thermal insulation material for an office building, specifically the management board seat of the Gdańsk Shipyard. The Sferolit coating, in the form of a 3 mm wet layer of gray spherulite, was applied in-house, delivering high-quality insulation and ensuring fast delivery time. This study highlights the benefits, challenges, and outcomes of using Sferolit coating for insulating structural walls.

Objective:

In this case study, our aim is to highlight the discovery of the effectiveness of Sferolit coating as a thermal insulation material for insulating structural walls in an office building. Our objective is to assess its suitability and explore the advantages of in-house application, including improved quality control and reduced delivery time. The study focuses on practical applications and the benefits derived from using Sferolit for efficient insulation solutions. Through this evaluation, we aim to provide valuable insights into the discovery of Sferolit's effectiveness in office building insulation, showcasing its potential for widespread use in the industry.

Methodology:

1. Material Selection: The decision to use Sferolit coating as a thermal insulation material was based on its properties, such as its insulating capabilities and ease of application.

2. Application Process: The Sferolit coating, in the form of a 3 mm wet layer, was applied directly onto the structural walls of the office building by an in-house team.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met the required standards and achieved the desired thermal insulation performance.

4. Delivery Time: The in-house application allowed for efficient planning and coordination, resulting in a fast delivery time for the project.

Results and Discussion:

1. Thermal Insulation Performance: The Sferolit coating effectively provided thermal insulation to the structural walls, helping to maintain a comfortable indoor temperature and reduce energy consumption.

2. Moisture Resistance: The application of the wet layer ensured a seamless and uniform coverage, minimizing the risk of moisture penetration and potential damage to the building.

3. In-house Application Benefits: By choosing to apply the Sferolit coating in-house, the management board of the Gdańsk Shipyard had better control over the quality of work, minimizing potential errors or delays.

4. Fast Delivery Time: The efficient planning and execution of the in-house application resulted in a significantly reduced delivery time compared to outsourcing the service.

Conclusion:

The case study demonstrates that the use of Sferolit coating as a thermal insulation material for the structural walls of the office building at the Gdańsk Shipyard was successful. The application of the 3 mm wet layer of gray spherulite ensured high-quality insulation and a fast delivery time. The in-house application allowed for better control over the quality of work and minimized potential delays. The Sferolit coating proved to be an efficient and effective solution for thermal insulation in this particular project.

Realisation 2

Sferolit Coating for Thermal Insulation of Devices in an Aromatic Oil Refinery in Bulgaria

Introduction:

This case study explores the successful use of Sferolit coating as a thermal insulation material on devices within an aromatic oil refinery located in Bulgaria, EU. The application involved the utilization of gray spherulite in a wet layer with a thickness of up to 3 mm, providing insulation from high temperatures of +120°C. The primary goal achieved through this application was to enhance energy efficiency, eliminate condensate, reduce energy losses, prevent thermal bridges, and maintain desired temperatures within the production facility. This study examines the benefits, challenges, and outcomes of using Sferolit coating for thermal insulation in this industrial setting.

Objective:

In this case study, our focus is to showcase the effectiveness of Sferolit coating as a thermal insulation material for devices in an aromatic oil refinery. We will assess the achieved goals, which encompass enhancing energy efficiency, eliminating condensate, reducing energy losses, preventing thermal bridges, and maintaining desired temperatures. Through this evaluation, we aim to highlight the practical benefits of utilizing Sferolit, demonstrating its ability to significantly improve the overall performance and reliability of the refinery's equipment.

Methodology:

1. Material Selection: Sferolit coating was selected based on its ability to provide effective thermal insulation and withstand high temperatures up to +120°C.

2. Application Process: Gray spherulite was applied as a wet layer with a thickness of up to 3 mm on the devices, ensuring comprehensive coverage and insulation performance.

3. Performance Assessment: Regular monitoring and evaluation were conducted to assess the effectiveness of Sferolit coating in achieving the desired goals.

4. Energy Efficiency Analysis: Energy consumption data and temperature measurements were analyzed to quantify the improvements in energy efficiency and temperature maintenance.

Results and Discussion:

1. Enhanced Energy Efficiency: The application of Sferolit coating significantly improved the energy efficiency of the devices within the aromatic oil refinery, reducing energy consumption and associated costs.

2. Elimination of Condensate: The thermal insulation properties of Sferolit coating prevented the formation of condensate, reducing the risk of corrosion and moisture-related issues.

3. Reduced Energy Losses: The insulation provided by the gray spherulite coating minimized energy losses, maximizing the effectiveness of the devices.

4. Prevention of Thermal Bridges: Sferolit coating effectively prevented the formation of thermal bridges, ensuring consistent and uniform temperature distribution throughout the facility.

5. Maintenance of Desired Temperatures: The application of Sferolit coating helped maintain the desired temperatures required for the production processes, optimizing operational efficiency.

Conclusion:

The case study demonstrates the successful application of Sferolit coating as a thermal insulation material on devices within an aromatic oil refinery in Bulgaria. The use of gray spherulite in a wet layer with a thickness of

REALISATION 3

Spherolith Coating for Thermal Insulation of a Sarcophagus at the Chernobyl Nuclear Power Plant, Ukraine

Introduction:

This case study examines the successful application of Spherolith coating as a thermal insulation material in a new sarcophagus constructed over an inactive nucleus at the Chernobyl nuclear power plant in Ukraine. The insulation covered several thousand square meters and aimed to reduce temperature differences and minimize the condensation effect, thereby enhancing the safety of the sarcophagus. Gray spherulite was used as the insulation material, applied through spraying to ensure high quality and quick delivery time. The project was carried out by a consortium, including VINCI Construction. This study investigates the benefits, challenges, and outcomes of using Spherolith coating for thermal insulation in the unique environment of a nuclear power plant.

Objective:

In this case study, our objective is to showcase the effectiveness of Spherulite coating as a thermal insulation material for the sarcophagus at the Chernobyl nuclear power plant. We will demonstrate how Spherulite successfully reduces temperature differences, minimizes condensation, and enhances the safety of the structure. Through this study, we aim to provide concrete evidence of how Spherulite actively contributes to improving the thermal performance and overall stability of the sarcophagus, ensuring the long-term safety and protection of the site.

Methodology:

1. Material Selection: Spherolith coating was selected for its thermal insulation properties and ability to reduce temperature differences and condensation effects.

2. Application Process: Gray spherulite was applied by spraying to ensure comprehensive coverage and insulation performance. The thickness of the insulation layer was 3 mm.

3. Safety Considerations: The project was executed with utmost care and adherence to safety protocols due to the unique environment of a nuclear power plant.

4. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

5. Timely Project Completion: The involvement of the consortium, including VINCI Construction, facilitated efficient project planning and execution, resulting in quick delivery time.

Results and Discussion:

1. Temperature Difference Reduction: The application of Spherolith coating effectively reduced temperature differences within the sarcophagus, mitigating potential structural issues caused by thermal expansion and contraction.

2. Minimization of Condensation: The insulation properties of gray spherulite coating minimized condensation, preventing moisture-related issues and preserving the integrity of the sarcophagus.

3. Enhanced Safety: The thermal insulation provided by Spherolith coating contributed to the overall safety of the sarcophagus, ensuring the stability and longevity of the structure.

4. High Quality and Quick Delivery: The spraying technique employed for applying the gray spherulite coating ensured high-quality insulation and facilitated a quick delivery time, meeting project deadlines.

Conclusion:

The case study demonstrates the successful use of Spherolith coating as a thermal insulation material in a sarcophagus at the Chernobyl nuclear power plant in Ukraine. The application of gray spherulite through spraying, with a thickness of 3 mm, achieved the intended goals of reducing temperature differences, minimizing condensation, and enhancing the safety of the structure. Spherolith coating proved to be an effective solution for thermal insulation in this unique environment, contributing to the stability and longevity of the sarcophagus. The involvement of the consortium, including VINCI Construction, ensured high quality, adherence to safety protocols, and timely project completion.

REALISATION 4

Sferolit Coating as a Highly Effective Thermal Insulation Material for Historic Hotel Building

Introduction:

This case study examines the successful utilization of Sferolit coating as a thermal insulation material for insulating walls and wooden ceilings in a historic hotel building located in Kluki near Bełchatów. The application involved using gray spherulite in a wet layer with a thickness of up to 3 mm. The investor performed the service themselves, ensuring high-quality insulation and a swift delivery time. This study investigates the advantages, challenges, and outcomes of using Sferolit coating for thermal insulation in a historic hotel building.

Objective:

In this case study, our focus is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for walls and wooden ceilings in a historic hotel building. Additionally, we aim to assess the benefits of the investor performing the service themselves, including quality control and timely completion. The study aims to provide insights into the practical application of Sferolit and highlight the advantages of in-house implementation for improved quality control and efficient project completion. Through this evaluation, we aim to demonstrate the potential of Sferolit coating in enhancing the thermal insulation of historic hotel buildings while offering advantages for investors who choose to undertake the insulation process themselves.

Methodology:

1. Material Selection: The decision to use Sferolit coating was made based on its insulating properties and compatibility with the building's requirements, particularly for walls and wooden ceilings.

2. Application Process: The investor performed the application, utilizing gray spherulite in a wet layer with a thickness of up to 3 mm. Application techniques were chosen to ensure proper coverage and insulation performance.

3. Quality Control: Regular inspections and testing were conducted to ensure adherence to quality standards and the achievement of desired thermal insulation effectiveness.

4. Timely Completion: The investor's hands-on involvement facilitated efficient planning and coordination, resulting in a swift completion of the project.

Results and Discussion:

1. Thermal Insulation Performance: The Sferolit coating effectively provided thermal insulation to the walls and wooden ceilings of the historic hotel building, contributing to enhanced energy efficiency and a comfortable indoor environment.

2. Preservation of Historic Features: The application of the wet layer allowed for seamless coverage and insulation without compromising the aesthetic and structural integrity of the historic building.

3. Investor's Involvement Benefits: By performing the service themselves, the investor ensured meticulous attention to detail, quality control, and minimized potential delays that could arise from outsourcing the work.

4. Timely Completion: The hands-on approach of the investor led to efficient planning and execution, resulting in the project being completed within a shorter timeframe.

Conclusion:

The case study demonstrates that the use of Sferolit coating as a thermal insulation material for walls and wooden ceilings in the historic hotel building in Kluki near Bełchatów was highly successful. The application of gray spherulite in a wet layer with a thickness of up to 3 mm ensured effective thermal insulation while preserving the building's historic features. The investor's involvement allowed for meticulous attention to detail, quality control, and timely completion. Sferolit coating proved to be an efficient and suitable solution for thermal insulation in this historic hotel building project.

REALISATION 5

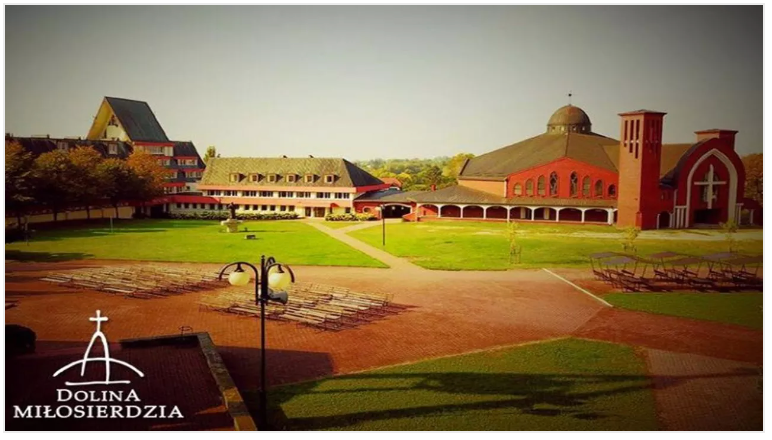

Sferolit Coating as an Effective Thermal Insulation Solution for a Sacral Building in Częstochowa

Introduction:

This case study examines the successful implementation of Sferolit coating as a thermal insulation material for insulating the walls of a sacral building located in Częstochowa, just 900m from Jasna Góra. The application involved the use of gray spherulite in a wet layer with a maximum thickness of 3 mm. The construction company SKALBUD from Kielce performed the service, ensuring high-quality insulation and a fast delivery time. This study explores the advantages, challenges, and outcomes of using Sferolit coating for thermal insulation in a sacral building.

Objective:

This case study aims to evaluate the effectiveness of Sferolit coating as a thermal insulation material for the walls of a sacral building. Additionally, it seeks to assess the benefits of the construction company SKALBUD performing the service, including quality control and timely project completion. The study focuses on understanding the practical application of Sferolit and highlights the advantages of having SKALBUD handle the project, ensuring optimal quality control and efficient completion. Through this evaluation, we aim to demonstrate the potential of Sferolit coating in enhancing thermal insulation for sacral buildings while showcasing the benefits of entrusting the project to SKALBUD for a successful outcome.

Methodology:

1. Material Selection: Sferolit coating was chosen based on its thermal insulation properties and suitability for the building's wall insulation requirements.

2. Application Process: The construction company SKALBUD applied the gray spherulite in a wet layer, ensuring a uniform coating with a maximum thickness of 3 mm.

3. Quality Control: Regular inspections and tests were conducted to ensure the application adhered to quality standards, achieving the desired thermal insulation performance.

4. Timely Project Completion: The involvement of SKALBUD facilitated efficient project planning and execution, resulting in a fast delivery time.

Results and Discussion:

1. Effective Thermal Insulation: The application of Sferolit coating provided efficient thermal insulation to the walls of the sacral building, contributing to improved energy efficiency and a comfortable indoor environment.

2. Moisture Protection: The wet layer application technique ensured seamless coverage, minimizing the risk of moisture penetration and potential damage to the building.

3. Construction Company's Expertise: SKALBUD's involvement allowed for professional execution, quality control, and the utilization of construction industry best practices.

4. Fast Delivery Time: The efficient project planning and execution by SKALBUD resulted in a significantly reduced delivery time, meeting project deadlines.

Conclusion:

The case study demonstrates the successful use of Sferolit coating as a thermal insulation material for the walls of a sacral building in Częstochowa. The application of gray spherulite in a wet layer with a maximum thickness of 3 mm provided effective thermal insulation while maintaining the building's integrity. The involvement of the construction company SKALBUD ensured high-quality insulation, adherence to standards, and timely project completion. Sferolit coating proved to be an efficient and suitable solution for thermal insulation in this sacral building project.

REALISATION 6

Sferolit Coating for Thermal Insulation of Devices in a Food Sector Industrial Facility in Bulgaria

Introduction:

This case study examines the successful implementation of Sferolit coating as a thermal insulation material on devices within an industrial facility in the food sector located in Bulgaria, EU. The application involved using gray spherulite in a wet layer with a thickness of up to 3 mm, providing insulation from high temperatures of +120°C. The primary goals achieved through this application were to enhance energy efficiency, increase energy savings, improve health and safety by preventing burns, eliminate condensate, and lower the temperature outside the devices by a significant percentage. This study investigates the benefits, challenges, and outcomes of using Sferolit coating for thermal insulation in this specific industrial setting.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for devices in a food sector industrial facility. We will assess the achieved goals, which include enhancing energy efficiency, increasing energy savings, improving health and safety, eliminating condensate, and lowering the external device temperature. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the overall performance and operational efficiency of devices in the food sector industrial facility.

Methodology:

1. Material Selection: Sferolit coating was chosen for its ability to provide effective thermal insulation and withstand high temperatures of +120°C.

2. Application Process: Gray spherulite was applied as a wet layer with a thickness of up to 3 mm on the devices, ensuring comprehensive coverage and insulation performance.

3. Performance Assessment: Regular monitoring and evaluation were conducted to assess the effectiveness of Sferolit coating in achieving the desired goals.

4. Energy Analysis: Energy consumption data and temperature measurements were analyzed to quantify the improvements in energy efficiency, savings, and temperature reduction.

Results and Discussion:

1. Enhanced Energy Efficiency: The application of Sferolit coating significantly improved the energy efficiency of the devices in the food sector industrial facility, resulting in reduced energy consumption and associated cost savings.

2. Increased Energy Savings: The thermal insulation properties of Sferolit coating led to increased energy savings by minimizing heat loss from the devices.

3. Improved Health and Safety: By effectively insulating the devices, Sferolit coating prevented burns and enhanced workplace safety for employees working in close proximity to the devices.

4. Elimination of Condensate: The insulation provided by the gray spherulite coating prevented the formation of condensate, reducing the risk of moisture-related issues and equipment damage.

5. Temperature Reduction: Sferolit coating effectively lowered the temperature outside the devices by a significant percentage, contributing to a more comfortable working environment and potentially reducing the load on cooling systems.

Conclusion:

The case study demonstrates the successful use of Sferolit coating as a thermal insulation material on devices within a food sector industrial facility in Bulgaria. The application of gray spherulite in a wet layer with a thickness of up to 3 mm achieved the intended goals of enhancing energy efficiency, increasing energy savings, improving health and safety, eliminating condensate, and lowering the external device temperature. Sferolit coating proved to be an effective solution for thermal insulation in this industrial setting, providing numerous benefits such as cost savings, improved safety, and enhanced working conditions.

REALISATION7

Sferolit Coating for Thermal Insulation of a Luxury Apartment Building on the Black Sea Shore in Odessa

Introduction:

This case study examines the successful application of Sferolit coating as a thermal insulation material in the construction of a new luxury apartment building on the shores of the Black Sea in Odessa. The use of Sferolit coating allowed for effective protection of external surfaces against moisture penetration and increased the thermal resistance index of ceilings and foundations, reducing heat loss. Gray spherulite was used as the insulation material, mechanically applied through spraying to ensure high quality and quick service delivery. The thermal insulation area covered by Sferolit coating on the building was 1,500.00 m2. The construction was implemented between 2017 and 2018. This study investigates the benefits, challenges, and outcomes of using Sferolit coating for thermal insulation in this seaside apartment building.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for a luxury apartment building located on the Black Sea shore in Odessa. We will assess the achieved goals, which encompass protection against moisture penetration and reducing heat loss in ceilings and foundations. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the insulation performance and overall comfort of the luxury apartment building, ensuring a pleasant living environment while minimizing energy consumption.

Methodology:

1. Material Selection: Sferolit coating was chosen for its thermal insulation properties and ability to protect against moisture penetration.

2. Application Process: Gray spherulite was mechanically applied through spraying to ensure comprehensive coverage and insulation performance. The insulation layer thickness was 3 mm.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

4. Timely Service Delivery: The spraying technique employed for applying the gray spherulite coating facilitated quick service delivery, meeting project timelines.

Results and Discussion:

1. Moisture Protection: The use of Sferolit coating effectively protected external surfaces against moisture penetration, preserving the integrity of the building and reducing the risk of water-related damage.

2. Heat Loss Reduction: The thermal insulation properties of the gray spherulite coating increased the thermal resistance index of ceilings and foundations, minimizing heat loss and improving energy efficiency.

3. High Quality and Quick Service Delivery: The mechanically sprayed application of the insulation material ensured high-quality coverage and facilitated quick service delivery, meeting project timelines and minimizing disruptions.

Conclusion:

The case study demonstrates the successful use of Sferolit coating as a thermal insulation material in a luxury apartment building on the Black Sea shore in Odessa. The application of gray spherulite through spraying, with a thickness of 3 mm, achieved the intended goals of protecting external surfaces against moisture penetration and reducing heat loss in ceilings and foundations. Sferolit coating proved to be an effective solution for thermal insulation in this seaside environment, contributing to the durability and energy efficiency of the building. The mechanically applied insulation material ensured high quality and quick service delivery, meeting project timelines and minimizing disruptions.

REALISATION 8

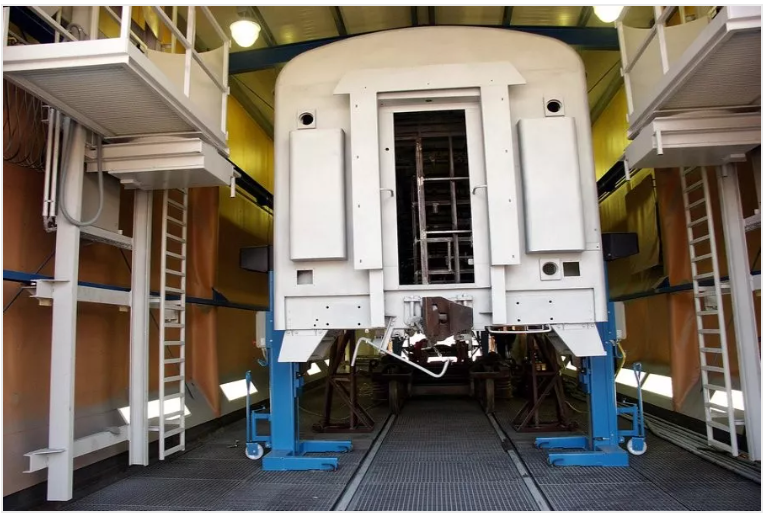

Sferolit Coating for Protection and Painting of Rail Transport Passenger Cars

Introduction:

This case study explores the successful implementation of Sferolit coating for the protection and painting of car bodies in passenger and freight railway cars. The rail transport industry utilizes modern technologies and innovative materials to enhance production processes, repairs, and construction of new cars. The surface preparation of car bodies involves blasting, applying anti-corrosion material, and an external paint coating using high-quality enamels. The modernization also includes the application of protective coatings such as galvanizing, priming, and the use of Sferolit thermal insulation for passenger cars. Additionally, passenger cars are equipped with heating, cooling, air humidity control systems, closed air circulation, and multi-stage filtration. Comparative tests have demonstrated the superiority of Sferolit in terms of technical and physical values compared to similar products from other countries. This case study evaluates the benefits, outcomes, and successful adoption of Sferolit coating in the rail transport industry.

Objective:

In this case study, our objective is to assess the effectiveness of Sferolit coating in providing protection and painting for passenger and freight railway cars. We will examine the advantages of Sferolit's dual protection system, which includes "active" cathodic protection and a "passive" protective barrier. Additionally, this study investigates the successful implementation of Sferolit thermal insulation in passenger cars, meeting regulatory requirements for heat loss prevention, and reducing noise and vibration. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in enhancing the protection, performance, and comfort of railway cars, contributing to the overall efficiency and quality of railway transportation.

Methodology:

1. Surface Preparation: Car bodies undergo blasting to prepare the surface for coating application.

2. Protective Coating Application: The process includes galvanizing, priming, and the application of Sferolit coating for thermal insulation and acoustic protection.

3. Quality Control: Tests and comparative analysis are conducted to compare the technical and physical values of Sferolit with similar products from other countries.

4. Implementation and Modernization: PJSC “DNIPRVAGONOREMSTROY” utilized over 140,000 liters of Sferolit coating to modernize 270 passenger cars from 2013 to the present.

Results and Discussion:

1. Enhanced Protection: The combination of galvanizing, priming, and Sferolit coating provides robust protection against corrosion, ensuring the longevity and durability of railway cars.

2. Insulation and Acoustic Benefits: Sferolit thermal insulation coating meets regulatory requirements for heat loss prevention and reduces noise and vibration, enhancing passenger comfort.

3. Comparative Advantage: Comparative tests have demonstrated the superior technical and physical values of Sferolit compared to similar products from other countries, positioning it as a leader in nano-thermal insulation in Europe.

4. Successful Implementation: The adoption of Sferolit coating by PJSC “DNIPRVAGONOREMSTROY” allowed for the modernization of 270 passenger cars, improving their performance and meeting regulatory standards.

Conclusion:

The case study showcases the successful utilization of Sferolit coating for the protection and painting of car bodies in rail transport passenger cars. The application of Sferolit coating, along with galvanizing and priming, ensures robust corrosion protection and longevity of the railway cars. Moreover, Sferolit's thermal insulation properties contribute to heat loss prevention, noise reduction, and enhanced passenger comfort. The comparative advantage of Sferolit over similar products from other countries further solidifies its position as a leader in nano-thermal insulation in Europe. The successful implementation by PJSC “DNIPRVAGONOREMSTROY” in modernizing 270 passenger cars highlights the effectiveness and benefits of Sferolit coating in the rail transport industry.

REALISATION 9

Sferolit Coating for Thermal Modernization of Administrative and Appeal Court Buildings

Introduction:

This case study focuses on the successful implementation of Sferolit coating for the thermal modernization of administrative and appeal court buildings located in the former Military District of Odessa, Ukraine. The project aimed to reconstruct multiple buildings and improve thermal efficiency to develop the area. Sferolit coating was chosen as a thermal insulation material to provide effective protection against moisture penetration and enhance the thermal resistance of external walls. The coating, applied mechanically through spraying, ensured high quality and quick service delivery. The thermal insulation area covered by Sferolit coating was 7,500.00 m2. The buildings underwent strict monitoring by the conservator of monuments, ensuring compliance with preservation requirements. The thermal modernization was conducted between 2017 and 2018. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the thermal modernization of the administrative and appeal court buildings.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in providing thermal insulation and protection against moisture penetration for the administrative and appeal court buildings. We will assess the achieved goals, which include enhancing the thermal resistance of external walls and meeting the preservation requirements set by the conservator of monuments. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the energy efficiency and durability of the court buildings while ensuring compliance with preservation regulations.

Methodology:

1. Material Selection: Sferolit coating was chosen as the thermal insulation material for its ability to provide effective protection against moisture penetration and enhance thermal resistance.

2. Application Process: The mechanically applied spraying technique ensured comprehensive coverage and efficient service delivery. The insulation layer had a thickness of 3.5 mm and was covered with white façade plaster.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

4. Preservation Compliance: The project was monitored by the conservator of monuments to ensure adherence to preservation requirements.

Results and Discussion:

1. Moisture Protection: The use of Sferolit coating effectively protected external surfaces against moisture penetration, safeguarding the integrity of the administrative and appeal court buildings.

2. Heat Loss Reduction: The thermal insulation properties of Sferolit coating increased the thermal resistance of external walls, minimizing heat loss and improving energy efficiency.

3. High Quality and Quick Service Delivery: The mechanically sprayed application of Sferolit coating ensured high-quality coverage and facilitated quick service delivery, meeting project timelines and minimizing disruptions.

4. Preservation Compliance: The strict monitoring by the conservator of monuments ensured that the thermal modernization project followed preservation requirements for the buildings.

Conclusion:

The case study demonstrates the successful use of Sferolit coating for the thermal modernization of administrative and appeal court buildings in the former Military District of Odessa. The application of Sferolit coating, with a thickness of 3.5 mm and covered with white façade plaster, provided effective protection against moisture penetration and enhanced the thermal resistance of external walls. The project adhered to preservation requirements set by the conservator of monuments, ensuring the integrity of the buildings. The use of mechanically sprayed Sferolit coating contributed to high-quality coverage and quick service delivery, meeting project timelines and minimizing disruptions. The thermal modernization improved energy efficiency and reduced heat loss, enhancing the sustainability and comfort of the administrative and appeal court buildings.

REALISATION10

Sferolit Coating for Thermal Insulation of "Nowa Arkadia" and "Korona Arkadia" Housing Estates

Introduction:

This case study focuses on the successful implementation of Sferolit coating as a thermal insulation material for the "Nowa Arkadia" and "Korona Arkadia" housing estates. The objective of the project was to provide effective thermal insulation and protection for concrete strips. Sferolit coating was applied with a 3mm thickness to enhance the thermal resistance of external walls and protect against moisture penetration. The gray Sferolit coating was mechanically applied, ensuring high-quality coverage and efficient service delivery. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the thermal insulation of the housing estates' concrete strips.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for concrete strips in the "Nowa Arkadia" and "Korona Arkadia" housing estates. We will assess the achieved goals, which include providing effective thermal insulation, protecting against moisture penetration, and enhancing the thermal resistance of external walls. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the energy efficiency, durability, and comfort of the housing estates, ensuring a pleasant living environment while minimizing energy consumption.

Methodology:

1. Material Selection: Sferolit coating was chosen as the thermal insulation material for its ability to provide effective protection against moisture penetration and enhance thermal resistance.

2. Application Process: The mechanically applied method ensured comprehensive coverage and efficient service delivery. The insulation layer had a thickness of 3mm and was applied in gray color.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

Results and Discussion:

1. Moisture Protection: The use of Sferolit coating effectively protected the concrete strips against moisture penetration, safeguarding their integrity and preventing potential damage.

2. Heat Loss Reduction: The thermal insulation properties of Sferolit coating increased the thermal resistance of external walls, minimizing heat loss and improving energy efficiency in the housing estates.

3. High Quality and Efficient Application: The mechanically applied Sferolit coating ensured high-quality coverage and efficient service delivery, meeting project timelines and minimizing disruptions.

4. Enhanced Building Performance: The thermal insulation provided by Sferolit coating contributed to improved comfort levels within the housing estates, reducing heat loss and enhancing energy efficiency.

Conclusion:

The case study demonstrates the successful utilization of Sferolit coating as a thermal insulation material for the "Nowa Arkadia" and "Korona Arkadia" housing estates. The application of Sferolit coating with a 3mm thickness effectively protected the concrete strips against moisture penetration and increased the thermal resistance of external walls. The gray-colored Sferolit coating, applied mechanically, ensured high-quality coverage and efficient service delivery. The thermal insulation properties of Sferolit coating enhanced building performance, reducing heat loss and improving energy efficiency within

REALISATION 11

Sferolit Coating for Thermal Insulation of Hotel and Residential Complex

Introduction:

This case study focuses on the successful implementation of Sferolit coating as a thermal insulation material for the walls of a hotel and residential complex. The project aimed to provide effective thermal insulation and protection for the walls. Sferolit coating, with a thickness of 3mm, was used to increase the thermal resistance index and safeguard against moisture penetration. The Sferolit coating was colored to match the façade and applied mechanically, ensuring high-quality coverage and efficient service delivery. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the thermal insulation of the hotel and residential complex walls.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for the walls of a hotel and residential complex. We will assess the achieved goals of providing effective thermal insulation, protecting against moisture penetration, and enhancing the thermal resistance index of the external walls. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving energy efficiency, ensuring a comfortable living environment, and enhancing the overall performance and durability of the hotel and residential complex.

Methodology:

1. Material Selection: Sferolit coating was chosen as the thermal insulation material for its ability to provide effective protection against moisture penetration and enhance thermal resistance.

2. Application Process: The mechanically applied method ensured comprehensive coverage and efficient service delivery. The insulation layer had a thickness of 3mm and was colored to match the façade.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

Results and Discussion:

1. Moisture Protection: The use of Sferolit coating effectively protected the walls against moisture penetration, preserving their integrity and preventing potential damage.

2. Heat Loss Reduction: The thermal insulation properties of Sferolit coating increased the thermal resistance index of external walls, minimizing heat loss and improving energy efficiency in the hotel and residential complex.

3. Aesthetically Pleasing: The Sferolit coating was colored to match the façade, ensuring a seamless and visually appealing appearance for the hotel and residential complex.

4. High-Quality Application: The mechanically applied Sferolit coating ensured high-quality coverage and efficient service delivery, meeting project timelines and minimizing disruptions.

Conclusion:

The case study demonstrates the successful utilization of Sferolit coating as a thermal insulation material for the walls of a hotel and residential complex. The application of Sferolit coating with a 3mm thickness effectively protected the walls against moisture penetration and increased the thermal resistance index of external walls. The Sferolit coating, colored to match the façade, provided an aesthetically pleasing appearance for the hotel and residential complex. The mechanically applied Sferolit coating ensured high-quality coverage and efficient service delivery. The thermal insulation provided by Sferolit coating contributed to improved energy efficiency, reducing heat loss in the hotel and residential complex. This successful implementation showcases the benefits and effectiveness of Sferolit coating for thermal insulation and protection of walls in hospitality and residential buildings.

REALISATION12

Sferolit Coating for Under-Building Passage Insulation - Heat Loss Prevention, Moisture Protection, and Energy Savings

Introduction:

This case study focuses on the successful implementation of Sferolit coating for insulating the passage under a building. The project aimed to utilize Sferolit coating to isolate apartments from heat loss, protect against moisture, and maintain the original structure and dimensions of the building. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for under-building passage insulation.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in insulating the under-building passage. We will assess the achieved goals, which include heat loss prevention, moisture protection, and energy savings while maintaining the structure and dimensions of the building. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in enhancing the thermal efficiency and durability of the under-building passage, ensuring optimal energy conservation and protection against moisture, while preserving the integrity of the overall building structure.

Methodology:

1. Material Selection: Sferolit coating was chosen for its properties that effectively insulate against heat loss and protect against moisture while maintaining flexibility.

2. Application Process: The Sferolit coating, in a 5mm thickness, was carefully applied to the under-building passage, ensuring comprehensive coverage and effective insulation.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on heat loss prevention, moisture protection, and energy savings.

Results and Discussion:

1. Heat Loss Prevention: Sferolit coating successfully prevented heat loss from the under-building passage, ensuring improved energy efficiency and reducing heating costs for the apartments above.

2. Moisture Protection: The application of Sferolit coating effectively protected against moisture, reducing the risk of damage to the building structure and ensuring a healthier living environment for residents.

3. Conservation of Building Structure and Dimensions: By replacing traditional insulation with a 5mm thick layer of Sferolit coating, the original structure and dimensions of the building were maintained, avoiding the need for major modifications or alterations.

4. Flexible Structure and Gap Filling: Sferolit coating's flexible structure enabled effective gap filling, preventing possible micro-cracks and ensuring a seamless and durable insulation solution.

Conclusion:

The case study demonstrates the successful implementation of Sferolit coating for under-building passage insulation. The use of Sferolit coating effectively achieved the objectives of heat loss prevention, moisture protection, and energy savings while maintaining the original structure and dimensions of the building. The coating successfully prevented heat loss, leading to reduced heating costs for the apartments above. Additionally, it provided effective moisture protection, ensuring a healthier living environment and preserving the integrity of the building structure. By replacing traditional insulation with a 5mm thick layer of Sferolit coating, the need for major modifications or alterations was avoided, resulting in cost and time savings. The flexible structure of Sferolit coating allowed for precise gap filling, minimizing the risk of micro-cracks and ensuring a seamless and durable insulation solution. This successful application highlights the benefits and effectiveness of Sferolit coating for under-building passage insulation, offering energy-efficient, moisture-resistant, and non-intrusive solutions for improving the thermal performance of buildings.

REALISATION 13

Sferolit Coating for Thermal Insulation of High School Buildings

Introduction:

This case study focuses on the successful implementation of Sferolit coating as a thermal insulation material for the walls of high school buildings. The project aimed to provide effective thermal insulation and protection for the external surfaces and walls. Sferolit coating, with a thickness of 3mm, was used to increase the thermal resistance and safeguard against moisture penetration. The Sferolit coating was colored to match the façade and applied mechanically, ensuring high-quality coverage and quick delivery time. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the thermal insulation of high school buildings.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating as a thermal insulation material for the walls of high school buildings. We will assess the achieved goals, which include providing effective thermal insulation, protecting against moisture penetration, and enhancing the thermal resistance of external walls. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving energy efficiency, creating a comfortable learning environment, and enhancing the overall performance and durability of high school buildings.

Methodology:

1. Material Selection: Sferolit coating was chosen as the thermal insulation material for its ability to provide effective protection against moisture penetration and enhance thermal resistance.

2. Application Process: The mechanically applied method ensured comprehensive coverage and quick delivery time. The insulation layer had a thickness of 3mm and was colored to match the façade.

3. Quality Control: Regular inspections and tests were conducted to ensure the application met quality standards and achieved the desired thermal insulation performance.

Results and Discussion:

1. Moisture Protection: The use of Sferolit coating effectively protected the external surfaces and walls against moisture penetration, preserving their integrity and preventing potential damage.

2. Heat Loss Reduction: The thermal insulation properties of Sferolit coating increased the thermal resistance of the walls, minimizing heat loss and improving energy efficiency in the high school buildings.

3. Aesthetically Pleasing: The Sferolit coating was colored to match the façade, ensuring a seamless and visually appealing appearance for the high school buildings.

4. High-Quality Application: The mechanically applied Sferolit coating ensured high-quality coverage and quick delivery time, meeting project timelines and minimizing disruptions.

Conclusion:

The case study demonstrates the successful utilization of Sferolit coating as a thermal insulation material for the walls of high school buildings. The application of Sferolit coating with a 3mm thickness effectively protected the walls against moisture penetration and increased the thermal resistance of the external surfaces. The Sferolit coating, colored to match the façade, provided an aesthetically pleasing appearance for the high school buildings. The mechanically applied Sferolit coating ensured high-quality coverage and quick delivery time. The thermal insulation provided by Sferolit coating contributed to improved energy efficiency, reducing heat loss in the high school buildings. This successful implementation highlights the benefits and effectiveness of Sferolit coating for thermal insulation and protection of walls in educational buildings.

REALISATION 14

Sferolit Coating for Insulation of Buses - Cooling, Energy Consumption Reduction, Acoustic Insulation, and Equipment Performance Enhancement

Introduction:

This case study focuses on the successful implementation of Sferolit coating for the insulation of buses. The project aimed to achieve multiple objectives, including cooling insulation, reduction of energy consumption, acoustic insulation, and enhancement of equipment performance. Sferolit coating was chosen as the insulation material for its effectiveness in meeting these objectives. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the insulation of buses.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating for insulation purposes in buses. We will assess the achieved goals, which include cooling insulation, reduction of energy consumption, acoustic insulation, and enhancement of equipment performance. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the overall comfort, energy efficiency, and performance of buses, ensuring a pleasant travel experience for passengers while minimizing energy consumption and reducing noise levels.

Methodology:

1. Material Selection: Sferolit coating was chosen as the insulation material due to its properties that contribute to cooling insulation, energy consumption reduction, acoustic insulation, and enhancement of equipment performance.

2. Application Process: The Sferolit coating was applied to the interior of the buses, ensuring comprehensive coverage and efficient insulation.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on cooling, energy consumption, acoustic insulation, and equipment performance.

Results and Discussion:

1. Cooling Insulation: Sferolit coating effectively contributed to cooling insulation within the buses, creating a comfortable environment for passengers and reducing the reliance on air conditioning systems.

2. Energy Consumption Reduction: The thermal insulation properties of Sferolit coating

REALISATION 15

Sferolit Coating for Thermomodernization of Sea and Cargo Containers - Internal and External Insulation to Prevent Condensation

Introduction:

This case study focuses on the successful implementation of Sferolit coating for the thermomodernization of sea and cargo containers. The project aimed to provide internal and external insulation to prevent condensation and improve thermal performance. Sferolit coating was chosen as the insulation material due to its ability to effectively isolate and prevent condensation. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for the thermomodernization of sea and cargo containers.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating for thermomodernization purposes in sea and cargo containers. We will assess the achieved goals, which include internal and external insulation to prevent condensation and improve thermal performance. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in enhancing the insulation capabilities of sea and cargo containers, preventing condensation issues, and improving overall thermal performance. This will contribute to better preservation of goods and materials during transportation while ensuring optimal energy efficiency.

Methodology:

1. Material Selection: Sferolit coating was chosen as the insulation material for its properties that effectively isolate and prevent condensation, improving thermal performance.

2. Application Process: The Sferolit coating was applied internally and externally to the sea and cargo containers, ensuring comprehensive insulation coverage and prevention of condensation.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on condensation prevention and thermal performance.

Results and Discussion:

1. Condensation Prevention: The application of Sferolit coating effectively isolated the sea and cargo containers, preventing condensation and its associated issues, such as corrosion and mold growth.

2. Thermal Performance Improvement: Sferolit coating contributed to improved thermal performance of the containers, reducing heat transfer and maintaining desired temperatures inside.

3. Enhanced Cargo Protection: The insulation properties of Sferolit coating provided a stable internal environment, protecting the cargo from temperature fluctuations and potential damage.

4. Long-Term Cost Savings: The prevention of condensation and improved thermal performance resulted in reduced maintenance costs and increased energy efficiency.

Conclusion:

The case study demonstrates the successful utilization of Sferolit coating for the thermomodernization of sea and cargo containers. The application of Sferolit coating effectively achieved the objectives of internal and external insulation to prevent condensation and improve thermal performance. The coating successfully isolated the containers, preventing condensation and its associated issues. Additionally, it contributed to improved thermal performance and enhanced cargo protection. The implementation of Sferolit coating resulted in long-term cost savings through reduced maintenance and improved energy efficiency. This successful application showcases the benefits and effectiveness of Sferolit coating for thermomodernization, ensuring the preservation and protection of sea and cargo containers.

REALISATION16

Sferolit Coating for HVAC Systems - Condensation Prevention, Soundproofing, Energy Savings, and Non-Combustibility

Introduction:

This case study focuses on the successful implementation of Sferolit coating for powering ventilation and air conditioning (HVAC) systems. The project aimed to utilize Sferolit coating to prevent condensation, soundproof the installations, and benefit from energy savings and non-combustible properties. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for HVAC systems.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in powering HVAC systems. We will assess the achieved goals, which include preventing condensation, soundproofing the installations, realizing energy savings, and leveraging its non-combustible properties. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in enhancing the performance and efficiency of HVAC systems, ensuring optimal thermal insulation, reduced energy consumption, noise reduction, and improved safety due to its non-combustible nature.

Methodology:

1. Material Selection: Sferolit coating was chosen for its properties that effectively prevent condensation, soundproof HVAC installations, provide energy savings, and offer non-combustibility.

2. Application Process: The Sferolit coating was applied to the HVAC components, ensuring comprehensive coverage and effective insulation and strengthening.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on condensation prevention, soundproofing, energy savings, and non-combustibility.

Results and Discussion:

1. Condensation Prevention: Sferolit coating successfully prevented condensation on HVAC components, reducing the risk of moisture-related damage and improving system longevity.

2. Soundproofing: The application of Sferolit coating contributed to soundproofing the HVAC installations, reducing noise levels and enhancing occupant comfort.

3. Energy Savings: The prevention of condensation and improved insulation provided by Sferolit coating resulted in reduced energy consumption, leading to significant cost savings and increased energy efficiency.

4. Non-Combustible Properties: Sferolit coating's non-combustible nature added an additional layer of safety and strength to the HVAC system, reducing the risk of fire hazards and enhancing overall durability.

Conclusion:

The case study demonstrates the successful implementation of Sferolit coating for powering HVAC systems. The use of Sferolit coating effectively achieved the objectives of condensation prevention, soundproofing installations, energy savings, and leveraging non-combustible properties. The coating successfully prevented condensation, reducing the risk of damage and extending the lifespan of HVAC systems. Additionally, it contributed to soundproofing the installations, providing a quieter and more comfortable indoor environment. The implementation of Sferolit coating resulted in significant energy savings through improved insulation, while its non-combustible properties enhanced safety and durability. This successful application highlights the benefits and effectiveness of Sferolit coating for powering HVAC systems, offering energy-efficient, low-maintenance, and safe solutions for ventilation and air conditioning installations.

REALISATION17

Sferolit Coating for Steam Boiler - Heat Loss Protection, Energy Savings, and Enhanced Safety

Introduction:

This case study focuses on the successful implementation of Sferolit coating for a steam boiler. The project aimed to utilize Sferolit coating to protect against heat loss, save energy, and enhance safety by reducing surface temperatures. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for heat loss protection in steam boilers.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in protecting against heat loss, saving energy, and enhancing safety in a steam boiler. We will assess the achieved goals, which include reducing surface temperatures and improving energy efficiency. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the thermal insulation of steam boilers, reducing heat loss, increasing energy efficiency, and ensuring a safer operating environment. The study will highlight the significant advantages of Sferolit in enhancing the performance and reliability of steam boilers.

Methodology:

1. Material Selection: Sferolit coating was chosen for its properties that effectively protect against heat loss and enhance safety by reducing surface temperatures.

2. Application Process: The Sferolit coating was applied to the outer surface of the steam boiler, ensuring comprehensive coverage and effective insulation.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on heat loss reduction, energy savings, and surface temperature reduction.

Results and Discussion:

1. Heat Loss Protection: Sferolit coating successfully protected against heat loss from the steam boiler, reducing energy waste and improving overall system efficiency.

2. Energy Savings: The application of Sferolit coating resulted in significant energy savings due to reduced heat loss, contributing to cost reductions and improved sustainability.

3. Enhanced Safety: Sferolit coating effectively reduced the surface temperature of the boiler, enhancing safety by minimizing the risk of burns or accidents for personnel working in close proximity to the equipment.

4. Surface Temperature Reduction: The use of Sferolit coating resulted in a thermal reduction of the outer surface temperature of the boiler from 94.5 degrees Celsius to 57.5 degrees Celsius, indicating a significant improvement in safety and comfort.

Conclusion:

The case study demonstrates the successful implementation of Sferolit coating for heat loss protection in a steam boiler. The use of Sferolit coating effectively achieved the objectives of heat loss reduction, energy savings, and enhanced safety. The coating successfully protected against heat loss, reducing energy waste and improving system efficiency. Additionally, it contributed to significant energy savings, resulting in cost reductions and improved sustainability. Sferolit coating enhanced safety by reducing the surface temperature of the boiler, minimizing the risk of burns or accidents for personnel. The thermal reduction of the outer surface temperature from 94.5 degrees Celsius to 57.5 degrees Celsius demonstrates the effectiveness of Sferolit coating in improving safety and comfort. This successful application highlights the benefits and effectiveness of Sferolit coating for heat loss protection in steam boilers, offering energy-efficient and safe solutions for the industry.

REALISATION18

Sferolit Coating for Tanker Insulation - Heat Prevention, Fuel Conservation, and Cost Savings

Introduction:

This case study focuses on the successful implementation of Sferolit coating for insulating tankers used for the transport of fuels and easily oxidizable gases or liquids. The project aimed to utilize Sferolit coating to prevent excessive heating of the tanks caused by the sun's rays, thereby reducing fuel loss due to evaporation. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for tanker insulation.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in preventing excessive heating of tankers, reducing fuel loss due to evaporation, and achieving cost savings. We will assess the achieved goals, which include heat prevention, fuel conservation, and measurable cost savings. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the thermal insulation of tankers, reducing heat transfer and fuel evaporation, and ultimately achieving significant cost savings. The study will highlight the positive impact of Sferolit in enhancing the efficiency and profitability of tanker operations.

Methodology:

1. Material Selection: Sferolit coating was chosen for its reflective properties, effectively preventing the tanks from heating up when exposed to the sun's rays.

2. Application Process: The Sferolit coating was applied to the exterior of the tankers, ensuring comprehensive coverage and effective heat prevention.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on heat prevention, fuel conservation, and cost savings.

Results and Discussion:

1. Heat Prevention: Sferolit coating successfully prevented excessive heating of the tankers by reflecting the sun's rays, reducing the risk of fuel evaporation and related losses.

2. Fuel Conservation: By preventing excessive heating and subsequent fuel evaporation, Sferolit coating effectively conserved the fuel being transported, resulting in significant fuel savings.

3. Cost Savings: The implementation of Sferolit coating led to immeasurable cost savings due to the reduced fuel loss and lower fuel consumption, contributing to overall operational efficiency and profitability.

Conclusion:

The case study demonstrates the successful implementation of Sferolit coating for tanker insulation. The use of Sferolit coating effectively achieved the objectives of heat prevention, fuel conservation, and cost savings. The coating successfully prevented excessive heating of the tankers by reflecting the sun's rays, reducing fuel evaporation and related losses. This led to significant fuel savings and immeasurable cost savings for the operation. The application of Sferolit coating highlights its effectiveness in protecting easily oxidizable gases or liquids during transportation, offering enhanced fuel conservation and improved operational efficiency. This successful application emphasizes the benefits and effectiveness of Sferolit coating for tanker insulation, providing an efficient and cost-effective solution for the transportation industry.

REALISATION 19

Sferolit Coating for District Heating Boiler Insulation - Heat Loss Prevention and Energy Savings

Introduction:

This case study focuses on the implementation of Sferolit coating for insulating a district heating boiler. The project aimed to utilize Sferolit coating to prevent heat loss from the boiler, thereby saving energy. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for district heating boiler insulation.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in preventing heat loss from a district heating boiler and achieving energy savings. We will assess the achieved goals, which include heat loss prevention and energy conservation. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the thermal insulation of district heating boilers, reducing heat transfer and minimizing energy loss. The study will highlight the positive impact of Sferolit in enhancing the efficiency and sustainability of district heating systems, leading to significant energy savings and environmental benefits.

Methodology:

1. Material Selection: Sferolit coating was chosen for its insulating properties, effectively preventing heat loss from the district heating boiler.

2. Application Process: The Sferolit coating was applied to the surfaces of the district heating boiler, ensuring comprehensive coverage and effective insulation.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on heat loss prevention and energy savings.

Results and Discussion:

1. Heat Loss Prevention: Sferolit coating successfully prevented heat loss from the district heating boiler, reducing energy waste and improving overall system efficiency.

2. Energy Savings: The application of Sferolit coating resulted in significant energy savings due to reduced heat loss, contributing to cost reductions and improved sustainability.

3. Improved System Efficiency: By insulating the district heating boiler with Sferolit coating, the system's overall efficiency was enhanced, leading to improved performance and reduced operational costs.

4. Thermal Comfort: The insulation provided by Sferolit coating not only prevented heat loss but also created a more comfortable environment by maintaining a stable temperature within the boiler.

Conclusion:

The case study demonstrates the successful implementation of Sferolit coating for district heating boiler insulation. The use of Sferolit coating effectively achieved the objectives of heat loss prevention and energy savings. The coating successfully prevented heat loss from the district heating boiler, reducing energy waste and improving system efficiency. This led to significant energy savings, contributing to cost reductions and improved sustainability. The application of Sferolit coating highlights its effectiveness in insulating district heating boilers, offering energy-efficient solutions for the industry. This successful application emphasizes the benefits and effectiveness of Sferolit coating for district heating boiler insulation, providing cost-effective and sustainable solutions for saving energy in heating systems.

REALISATION 20

Sferolit Coating for Motorhome Soundproofing and Insulation - Area Preservation and Fuel Savings

Introduction:

This case study focuses on the successful implementation of Sferolit coating for soundproofing and insulation in a motorhome. The project aimed to utilize Sferolit coating to provide soundproofing, insulation, and fuel savings for heating purposes. This case study examines the benefits, challenges, and outcomes of using Sferolit coating for motorhome soundproofing and insulation while preserving the original area.

Objective:

In this case study, our objective is to evaluate the effectiveness of Sferolit coating in providing soundproofing, insulation, and fuel savings in a motorhome. We will assess the achieved goals, which include soundproofing, insulation, and investor satisfaction. Through this evaluation, we aim to demonstrate the practical benefits of using Sferolit in improving the comfort and energy efficiency of motorhomes, reducing noise levels, enhancing insulation capabilities, and ultimately leading to fuel savings. The study will highlight the positive impact of Sferolit in creating a pleasant and efficient living environment in motorhomes while ensuring investor satisfaction.

Methodology:

1. Material Selection: Sferolit coating was chosen for its soundproofing and insulating properties, ensuring optimal performance in the motorhome.

2. Application Process: A light coating of Sferolit was carefully applied to the motorhome, providing soundproofing and insulation without reducing the original area.

3. Performance Evaluation: Regular assessments were conducted to evaluate the impact of Sferolit coating on soundproofing, insulation, and fuel savings.

Results and Discussion:

1. Soundproofing: Sferolit coating effectively provided soundproofing in the motorhome, reducing external noise and enhancing the overall comfort and tranquility for the occupants.

2. Insulation: The application of Sferolit coating ensured effective insulation, reducing heat loss and maintaining a comfortable interior temperature in the motorhome.

3. Fuel Savings: By preventing heat loss, Sferolit coating contributed to fuel savings for heating purposes, leading to reduced energy consumption and operational costs.

4. Area Preservation: The light coating of Sferolit coating allowed for insulation and soundproofing without reducing the original area of the motorhome, preserving its spaciousness and functionality.

5. Investor Satisfaction: The fulfillment of soundproofing, insulation, and fuel-saving goals through the use of Sferolit coating resulted in full satisfaction for the investor.

Conclusion: